new era

in the manufacture of wet wipes

arvell

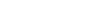

Harper Hygienics S.A. has partnered in the design of the worlds most highly developed technology of state of the art production of Arvell nonwoven fabric.

The Arvell technology is an innovative, patented solution which offers a new quality of wet wipes, the features of which are highly valued by our consumers. It not only has some of the most advanced performance features but it’s also eco friendly and gentle on the environment.

The project is a result of cooperation between Harper Hygienics and the Italian company Teknoweb, with the help of international experts in the field of cellulose research and technologies. Teknoweb - the world's leader in production of equipment used for hygienic products packaging is also the producer of the Arvell manufacturing equipment and owner of the technology.

The innovative Arvell technology received many awards, such as Premio dei Premii - a prestigious award granted by the Italian President Giorgio Neapolitano in 2013 for innovation by the Italian Industry Organization.

benefits of technology

new production standard

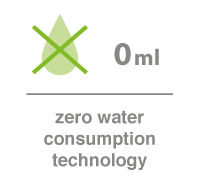

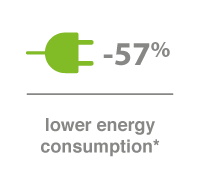

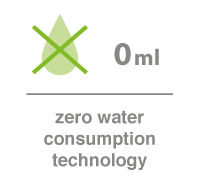

The new Arvell standard is friendly for the natural environment, with features that promote energy savings, water conservation and many other green energy initiatives. The practical application of these solutions results in the Arvell nonwoven fabric which offers a new and improved standard of quality and performance in the production of wet wipes.

natural softness

Thanks to a high content of natural components, the Arvell nonwoven fabric is soft to the touch, with a much more natural feel and texture.

comfort of use

The innovative structure of the fibers ensures both excellent absorption along with improved moistening of the wipes, which together helps to increase the cleaning efficiency. Consumers studies confirm that other parameters such as resistance, thickness and softness are kept at levels that contribute to a much greater comfort in their use.

attractive pattern

The Arvell technology allows to create fabrics with custom-designed patterns. The perfect quality of the pattern gives a far better visual effect as compared to fabrics available currently on the market, which further increases the aesthetics and pleasure of using the wipes.

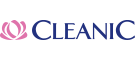

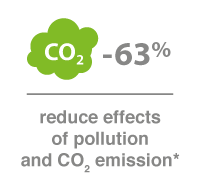

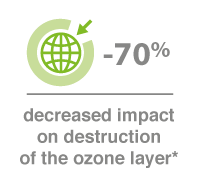

environmentally friendly technology

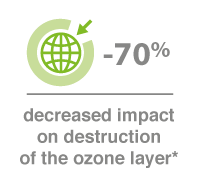

*compared to most popular wet wipes production technologies

Environmental friendliness of the technology has been confirmed by research

conducted by the University of Manchester

carbon

footprint

(t CO2 - eq/t)

5,85

2,18

carbon footprint

(t CO2 - eq/t) - means the total sum of greenhouse gas (CO2 carbon dioxide) emissions generated during product manufacture. The volumes of CO2 emitted into the environment depend on: consumption of utilities (power, gas, water, fuel oil, etc.) and type of raw materials used, which may have a high or a low CO2 emission level because of the life cycle of decomposition in the soil.fossil

fuel consumption

(GJ./t)

90,3

38,4

fossil fuel consumption

(GJ./t) - depletion of fossil fuels (fossil deposits) during manufacture (abiotic - affecting the ecosystem).acidification

(kg SO2 - eq/t)

46,7

11,9

acidification

(kg SO2 - eq/t) - impact of sulfur compounds emission (production waste, wastewater, flue gas) on acidification of the environment. As a result of high SO2 emission into the environment, water and soil may become overly acidified, which results in the death of trees and fish.

ozone

layer depletion

(mg CFC - 11 - eq./t)

291

89

ozone layer depletion

(mg CFC - 11 - eq./t) - coefficient defining the influence of greenhouse gas (gas, dust) emission contributing to the destruction of the ozone layer in the Earth's atmosphere.generation of

photochemical smog

(kg C2H2 - eq./t)

3,63

1,42

generation of photochemical smog

(kg C2H2 - eq./t) - during the manufacturing process, photochemical smog is generated which, when in contact with sunlight, results in the creation of ozone that may be toxic to humans.toxicity for

the human body

(kg DCB - eq/t)

1789

681

toxicity for the human body

(kg DCB - eq./t) ) - defines the influence of production waste, wastewater and flue gases on human health.fresh water

toxicity

(kg DCB - eq/t)

1131

532

fresh water toxicity

(kg DCB - eq./t) - defines the influence of production waste, wastewater and flue gases effecting the purity of fresh water and the health of freshwater organisms.application

Ultimately, the Arvell technology will allow to create fabrics with parameters adapted to suit individual consumer needs, such as thickness of the fabric, pattern or fiber composition.

The Arvell nonwoven fabric is used in Harper Hygienics products branded as Kindii baby wipes and Cleanic refreshing wipes and intimate wipes. It is also used in products manufactured by Harper Hygienics for international and local distribution chains.